The British Churchill tank was the only one supplied to the USSR by the Western Allies en masse. The US had bad luck with heavy tanks. Work on the Heavy Tank M6 hit a dead end. Nevertheless, heavy tanks did arrive in the American army by the end of the war. These were Heavy Tanks T26E3, standardized as M26 Pershing. However, the T26E3 was rather arbitrarily classified as heavy. In practice, this was a medium tank. Only its mass made it a heavy, and even then, it returned to medium after the war. This article is dedicated to the trials of the T26E3 in the USSR, during which it was compared to heavy tanks.

On the schedule

The T20/T23 tank program was launched in the US in mid-1942. These tanks were radically different from any other American design. Instead of a front transmission, which Harry Knox copied from the British Vickers Mk.E tank, these tanks had a classical layout with a rear transmission. The design of American tanks was gradually evolving, in no small part thanks to the study of foreign tanks. The USSR helped out here. The T-34 and KV-1 at the very least influenced the tanks of this family. Primarily, the influence touched the torsion bar suspension to replace VVSS. Even though this suspension was far from the first to be tried, it won out in the end.

The torsion bar equipped Medium Tank T23E3 was supposed to be standardized as the M27, but the electric transmission doomed this tank. Nevertheless, a part of this tank went into production. The turret was installed onto a Medium Tank M4 chassis, which noticeably improved the vehicle's effectiveness.

Heavy Tank T26E1, Aberdeen Proving Grounds, January 1945.

Further development focused on the T25 and T26 medium tanks, which received powerful 90 mm T7 (later M3) guns. The Medium Tank T26 was considered the optimal variant. However, during development, its mass increased to 41.9 tons. Because of this, the version of the tank that was put into production, the T26E3, was called a heavy tank. To compare, the American T23 medium tank weighed 34 tons. In a way, the American designers repeated the "success" of MAN's designers, who started developing the Panther in the 30 ton weight class and ended up with a 45 ton tank.

The Soviet military knew little about this evolution of the American tank. They first discovered the Medium Tank T20/T23 program in the summer of 1943, during a visit to the General Motors proving grounds. The meeting with this prospective tank was unplanned, a result of oversharing by Quentin Berg, one of the creators of the GMC M10 and GMC T70 (M18).

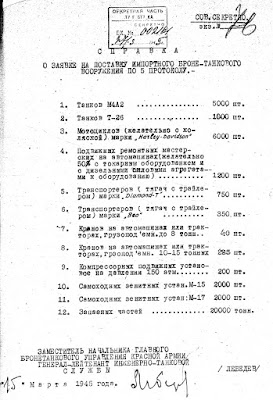

A request from the Red Army Main Armour Directorate for American military vehicles in 1945. As you can see, the M26 is present in large amounts.

More complete information began to come in by mid-1944. Soviet specialists already knew that the prospective tanks are available in various variants, differing in suspension and other elements. It was also known that the torsion bar suspension was not deemed optimal at first. According to information that was obtained, HVSS showed comparable results, which made the American waver. The Soviet military also knew that the Medium Tank T26 and Medium Tank T26E1 were upgraded to heavy tanks on July 25th, 1944. Production numbers were also on hand. According to them, the T23 would be the most numerous of the medium tanks, even though the T23 program was winding down in favour of the T25 or T26.

The manifest of the SS August Belmont, which brought the new American tank, among other cargo.

It was clear that the Americans gave the T26 priority by the end of 1944. According to information received on January 13th, 1945, production of 192 tanks of this type was planned during the first two months of 1945. The index M26 was already used at this point, applied to the T26E1. In reality, another vehicle was called M26, the T26E3, but that did not happen until March of 1945. Overall, 450 vehicles were planned for the first quarter of 1945, and 6000 during the entire year. It is not surprising that 1000 T26 and 5000 M4A2 tanks were included into the Soviet Lend Lease requests. The Americans were not opposed to these deliveries, provided that their army received sufficient tanks first. However, nobody opposed sending one M26 (T26E3) to the USSR.

Technically experimentall

A Heavy Tank T26E3 with registration number 30119961 was sent to the USSR for study. This was a production vehicle, but it was referred to as experimental by Soviet specialists. This was because the T26E1 initially held the index M26. The tank was loaded aboard the SS August Belmont, which also carried prime movers and 13 M4A2E8 medium tanks. The transport was a part of convoy JW-66, which set out for Murmanck on April 16th, 1945 and arrived on the 25th. Unlike JW-65, this convoy took no losses.

Heavy Tank T26E3 at the NIBT proving grounds, summer of 1945.

The tank arrived in Kubinka towards the end of May. A trials program was composed, which included a study of the vehicle, mobility tests, and trials of the armament. As it often happened, an issue arose with the last item. The tank arrived with no ammunition. Even though the USSR had M1 AA guns, whose ammunition was compatible with the M3 90 mm gun, some time was needed to receive them. Complaints about missing ammunition were lodged on May 24th. Considering that trials were completely by July, the issue was solved quickly.

View from the right. The tank is clearly distinct from its predecessors.

Traditionally for these trials, they began with a study of the tank. This process was made easier due to the large number of technical documents that arrived with it, including a manual for the tank and its gun. Two technical descriptions of the vehicle were composed: a brief one, included in the report, and a full one.

A reworked layout allowed the height to remain at the level of a regular M4A2.

It's easy to explain the high degree of interest towards the T26E3. First of all, this was the first American mass produced heavy tank, even if it was only heavy by mass. Second, the layout was radically different from that of the existing American medium and heavy tanks, as was the layout of all T20 tanks. The layout of the Vickers Mk.E was gone, and the transmission migrated to the rear. The Americans reached this idea in 1942. Funnily enough, a year later, Heinrich Kniepkamp decided to use the exact same concept on the E-50, E-75, and other E-series vehicles. The use of the classical layout allowed the T26E3 to become 20 cm lower than the M4A2(76)W. Its armour was thicker, and a turret with more powerful armament was installed.

Looking from behind, the engine compartment hatches are visible.

NIBT proving grounds specialists guessed that the design of the tank's components was close to that of the GMC T70. This was partially true, especially the suspension. The Americans tested their torsion bar suspension on the T70. The degree of resemblance of the T26E3 was not as high as that of the T20E3 and T23E3, which used the same track links, road wheels, and drive sprockets. It is easy to explain these similarities: all of these vehicles were designed at the Tank-Automotive Center in Detroit. The idler adjustment system that allowed the tracks to keep tight also migrated from the SPG to the tank, albeit with some changes.

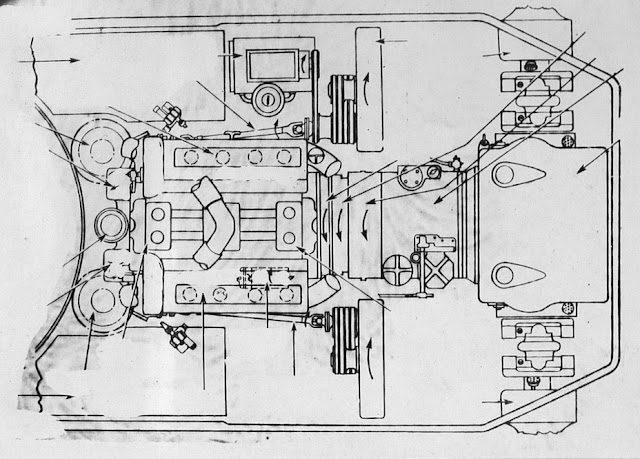

Overall diagram of the engine compartment.

The layout of the components in the engine compartment was deemed most interesting. The engine and transmission bays were separated with a block, on which the cooling system was installed. The testers remarked on the convenient access to components for service. The engine and transmission were joined into a single unit. This made it easier to install them into the compartment. However, this kind of solution had its drawbacks. First, the mass of the assembly was over two tons, which made it hard to remove in the field. Second, it was impossible to remove components individually, which also made field repairs difficult.

Engine and transmission assembly.

The transmission layout was another common factor between the T26E3 and GMC T70. Both vehicles had a Torqmatic Model 900-T gearbox and a torque converter. The gearbox, torque converted, and double differential were joined into one assembly. The biggest difference from the GMC T70 was that there was now a planetary speed reductor in between the engine and torque converter. It was put there for a good reason. Presumably, the issues experienced by the T70 off-road did not only plague Soviet testers. The installation of the reductor prevented the torque converter from slipping.

T26E3 transmission diagram.

A significant difference was the layout of the driver's compartment. It became much roomier after the transmission was moved to the rear. In addition, the driving controls were duplicated, making the assistant driver live up to his name. The driver could also set his seat to one of four positions.

The armour of the tank did not impress Soviet testers. This was not enough armour for a heavy tank.

Overall, the driver's compartment offered comfortable controls and good visibility. However, there was one problem. In October of 1945, after mobility trials were performed, trials were held to compare the effort required to drive tanks. Turning the tank in first gear at a minimum radius took 35 kg of effort on the right lever. To turn left smoothly, 32 kg of effort was required. Only the IS-3 needed greater strength to drive, although the M4A2(76)W was not far behind.

Visibility from the driver's compartment.

The design of the hull caused mixed feelings in the Soviet engineers. This was largely caused by the fact that the tank was branded as a heavy. The design of the hull that combined rolled and cast components was interesting. Its benefits included large hatches that made it easier to access components, as well as internal bulkheads, which made the hull more rigid. The biggest drawback was 101.6 mm of armour in the front. This was not enough for a heavy tank in 1945. Even protection of Soviet medium tanks that were being tested at the time was better. Another downside was the fan cap between the driver and his assistant. The final drive casings that protruded from the hull were also deemed a bad decision. There was a significant risk to damage the final drives by hitting mines or obstacles.

Fighting compartment visibility diagram.

The turret also did not boast exceptional armour, with the same 101.6 mm in front. Its design was a logical progression from the T23 turret, which was also used on the M4A2(76)W. A large bustle housed the radio equipment freely. Traditionally for American tanks, the visibility from the turret was good. Despite the enlarged turret, the Soviet testers deemed the commander's station somewhat cramped. However, the gunner's station was very comfortable. The gun aiming mechanisms were well designed. Trials showed that traversing the turret all the way around took 100 second by hand or 17 seconds using the powered traverse.

Ammunition racks on the floor of the fighting compartment.

One of the few complaints about the gunner's station was caused by the sights. They only had scales for armour piercing shells. It turned out to be quite inconvenient to fire HE shells and the coaxial machinegun with them. There were also complaints about low magnification. The loader's station was also well designed, but not without fault. The ammunition racks on the floor forced the loader to make additional movements, which reduced the rate of fire.

Soft and hungry going

Initially, it was planned that the tank would go through the standard cycle of mobility trials, including driving on a paved highway, dirt roads, and off-road. An order from the head of the Main Armour Directorate of the Red Army, General Fedorenko, came in right before the trials began, instructing the testers to shorten the program. As a result, the 1000 km distance was shortened to 500 km. Trials to determine the top speed, highway, and off-road driving were cancelled.

T26E3 during mobility trials.

Driving took place only on badly smashed up forest roads. This impacted the average speed, which was only 18.9 kph. It was deemed good, since it would clearly be higher in better conditions. Comparisons were made with other tanks that were tested on the same roads at about the same time. These were, primarily, the T-44 and IS-3 tanks. The IS-3's average speed in these conditions was 14.6 kph, and average technical speed was 11.1 kph. The T-44 drove at 17.5 kph and 15.5 kph respectively. A comparison with the American M4A4 medium tank was also made, which had average speeds of 16.5 and 14.8 kph. A Panther tank, the closest analogue of the Pershing, was also tested. Its speeds were 15.8 and 11.4 kph respectively.

The American heavy tank easily climbs up a prolonged slope.

The presence of a torque converted was considered a big plus. It gave the tank significant power, which was especially noticeable on slopes. The tank gained speed quickly. The driving was quite smooth, thanks to the torsion bar suspension and telescoping shock absorbers. The suspension absorbed small bumps, which led to an increase in average speed. The vehicle accelerated to 30 kph over 15 seconds, having travelled 68 meters.

A 31 degree descent did not cause any problems.

The cost for using a torque converter was record fuel consumption. The T26E3 consumed 585 L of fuel for 100 km of driving. In these conditions the IS-3 consumed 373 L of fuel, and the T-44 consumed 378 L. However, we must remember that the IS-3 and T-44 had diesel engines. The gasoline powered M4A4 and Panther consumed 503 and 595 L respectively. The testers explained the high fuel consumption with the low efficiency of the torque converter and the fact that the engine constantly worked at maximum output.

The GMC T70 had similar issues, but it also had significant issues with overcoming obstacles. Startup trials of the T26E3 showed that the installation of a planetary reductor largely solved these issues.

Driving at a tilt of 35 degrees.

The improved transmission affected the tank's performance on climbing and descending grades, as well as driving at an angle. It turned out that, as the instructions specified, the tank successfully drove at a tilt of 31-32 degrees. The maximum angle of descent, 31 degrees, was also the same as in the manual. The tank managed to overcome a 35 degree slope. The tank could also tow an IS-2 with no issues, however the fuel expenditure rose to 160 L per hour.

The biggest defect was the destruction of road wheel rims.

The tank demonstrated good mobility during trials. The only engine trouble was experienced on the 126th kilometer of the trials, and only then because the fan belt roller was installed incorrectly. The only transmission trouble happened on the 54th kilometer, when an oil pump roller broke. After it was repaired it broke once more, along the welding seam. It was then replaced by a newly manufactured part. The biggest issues were with the suspension. Significant wear of the drive sprocket teeth was observed. The rim of one of the road wheels was destroyed towards the end of the trials. Partial destruction of other road wheel rims was noticed later.

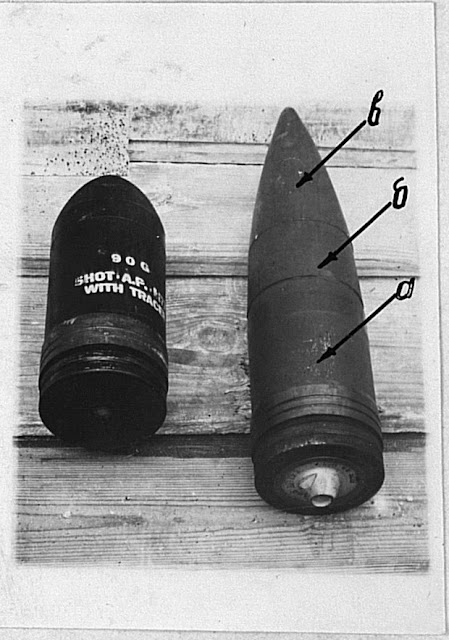

Armour piercing shells M77 (left) and M82.

The next stage was testing of the armament. The Heavy Tank T26E3 carried the M3 90 mm gun, which had the same ballistics as the M1 AA gun. By the time the trials began, both types of armour piercing shells were available, as well as HE shells. Trials showed a rate of fire of 6-7 RPM. Firing from short stops allowed for one shot in 11 seconds. Such a big time between shots was the result of significant oscillations of the tank after stopping. Precision during firing from short stops was deemed good.

The M82 shell demonstrated less impressive results.

While driving at a speed of 12-13 kph, a hit rate of 40-50% was attained, and 10-20% at 24-26 kph. Unlike the M4A2(76)W, the tank had no gyroscopic stabilizer, which impacted the results of the trials. The stability of the hull during firing was deemed satisfactory.

The situation with fumes in the fighting compartment was far from ideal. It turned out that the concentration of fumes was far in excess of acceptable norms. The concentration decreased when the fan was turned on, but was still very high.

Marks on the Tiger's armour after being shot from 1300 meters.

The results of the penetration trials were also mixed. Two types of shells were used: M77 without a cap, and M82 APCBC. Individual plates from a Tiger tank, installed at various angles, were used as targets. Trials showed that the M77 shell can penetrate an 82 mm thick plate at 50 degrees from 1300 meters. This result is similar to the performance of the German 88 mm KwK 36. The result was good, but German tanks, especially heavy ones, had much more powerful guns. The American gun slightly surpassed the Soviet 85 mm S-53 gun, but was worse than the 100 mm D-10.

Serious underestimation

The undeserved status of a heavy tank and the raised expectations resulted in a rather harsh verdict. While recognizing a number of positive qualities, the testers deemed that the T26E3 was not up to modern standards. However, the T26E3 was a medium tank, not a heavy one. The conclusion that this tank was experimental was also a big mistake. The Heavy Tank T26E3 successfully fought during the last months of WWII. However, the verdict about its weak armour was confirmed.

Five years later, the M26 Pershing was fighting in Korea, now as a medium tank. Its opponent here was the T-34-85, which it certainly surpassed. Nevertheless, it is hard to blame the testers for their evaluation of the American tank. It was considered heavy, and that meant that it was compared to German heavy tanks and the IS-3. The tank that was sent to the USSR did not survive to this day. It was sent to Leningrad after the trials, and it did not return.